Stainless steel is a corrosion resistant metal alloy. Its primary alloying metals are iron, chromium, and nickel. Some popular types of stainless steel include austenitic stainless steel, ferritic stainless steel, and martensitic stainless steel.

The most common grades of stainless steel are 304 and 316. They have a slightly different composition. 304 stainless steel, for example, has a higher chromium content and a lower nickel content than 316 stainless steel.

Stainless steel is widely used to manufacture industrial equipment and tools due to the following reasons.

Superior Corrosion Resistance

The chromium in stainless steel reacts with oxygen to create a thin passive layer of chromium oxide that prevents rust and corrosion in harsh environments. Stainless steel resists stains and rust better than regular steel even when exposed to moisture. Because 316 stainless steel is more corrosion resistant than 304 stainless steel, it is better suited for marine environments.Durability and Strength

Stainless steel has a high tensile strength (varies between 500 MPa and 620 MPa depending on the grade). It is also highly durable and can withstand heavy loads, mechanical stress, and high pressure. Its strength and durability make it ideal for a number of industrial applications. Though both grades are durable, 304 stainless steel offers better heat resistance and maintains its structural integrity in testing conditions.Heat Resistance

Another advantage of stainless steel is that it can withstand high temperatures without losing its properties. No wonder the alloy is used for heat treatment equipment, heat exchangers, and furnaces.Ease of Fabrication

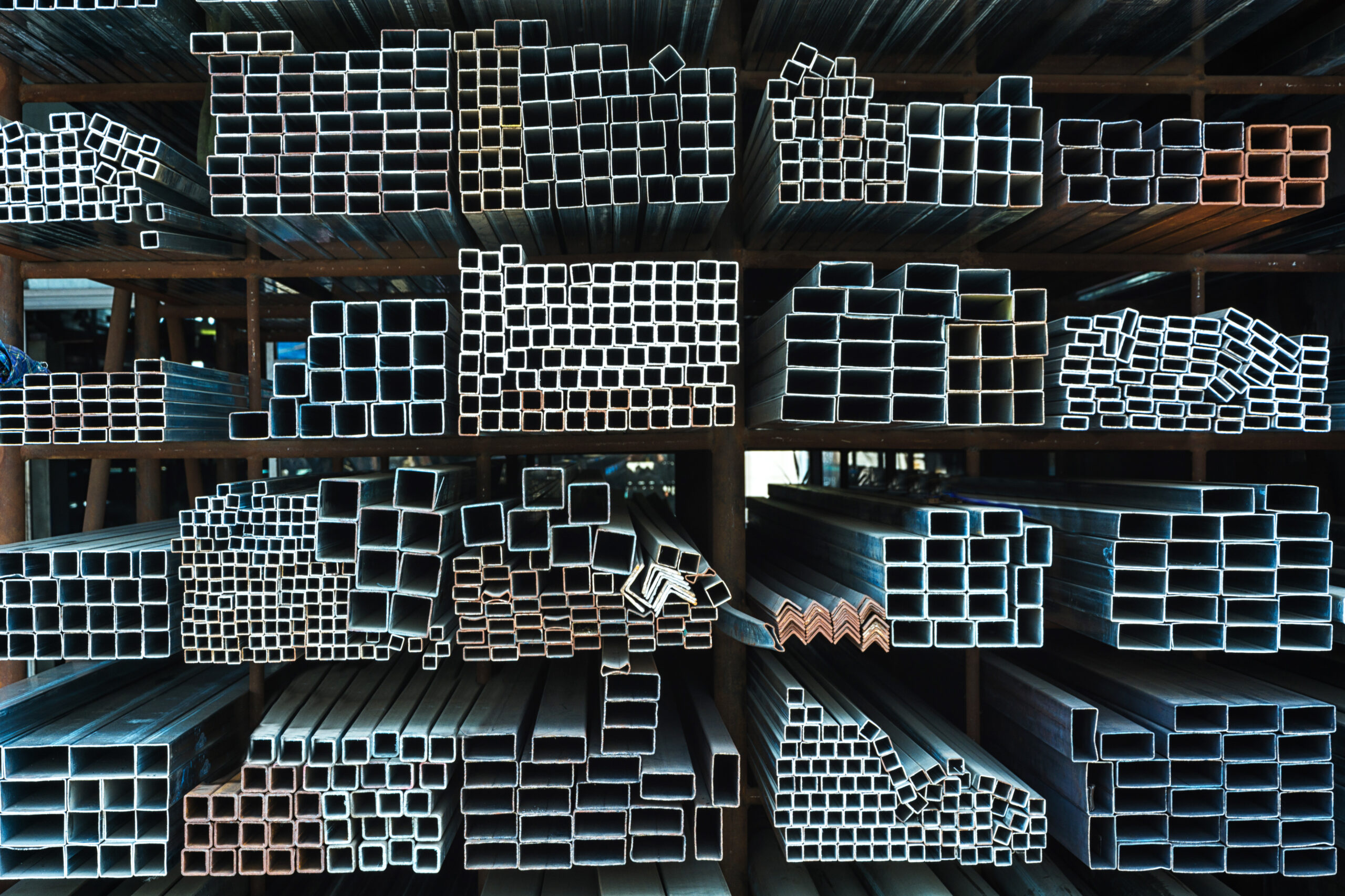

Stainless steel is one of the easiest metals to work with. It can be easily welded, machined, and fabricated into different shapes and sizes. For best results, use the right tools for fabricating stainless steel depending on the intended application.Aesthetics

Stainless steel’s shiny, reflective surface can be polished to achieve a variety of finishes. The shiny and lustrous metal is used in- Decorative elements such as borders, moldings, and trims

- Fancy logos and signs

- Decorative furniture

- Interior and exterior fixtures such as railings, cabinets, and countertops

Versatility

Stainless steel can be alloyed with different metals including molybdenum, titanium, and nickel to enhance the metal alloy’s specific property (can be heat and corrosion resistance or durability) depending on the application.It is Antimicrobial

The non-porous surface of stainless steel prevents microbial growth. It is also very easy to clean and is used in medical equipment, kitchen utensils, and food processing and storage equipment.Sustainability

Stainless steel is one of the most environmentally friendly materials. It is 100% recyclable. No wonder stainless steel products are the first choice of businesses that want to reduce their carbon footprint. Durable stainless steel products have a long lifespan and can help reduce pressure on landfills.Cost effectiveness

Though stainless steel may cost more than many other materials, its superior heat and corrosion resistance, minimal maintenance requirements, and long useful life make it a cost-effective option in the long run. Bayou Metal Supply & Manufacturing & Manufacturing is one of the most trusted stainless steel sheet metal suppliers in Louisiana. We have a variety of materials in different profiles. To learn more, call (877) 375-4800.Recent Post

- Why Is Stainless Steel The Most Preferred Material In Manufacturing Industrial Equipment And Tools?

- Aluminum Sheets Comparative Analysis: 5052 H32 vs 5052 H34

- Everything You Need To Know About Aluminum Alloy 5086 Sheet

- Join Bayou Metal Supply & Manufacturing at the 2024 International WorkBoat Show – Booth #2337

- What Makes T6 the Most Popular Temper for Aluminum 6061 Grade?