Manufacturing, Processing, & Fabrication Services That Keep

You On Schedule

Your Metals Delivered Ready for Assembly

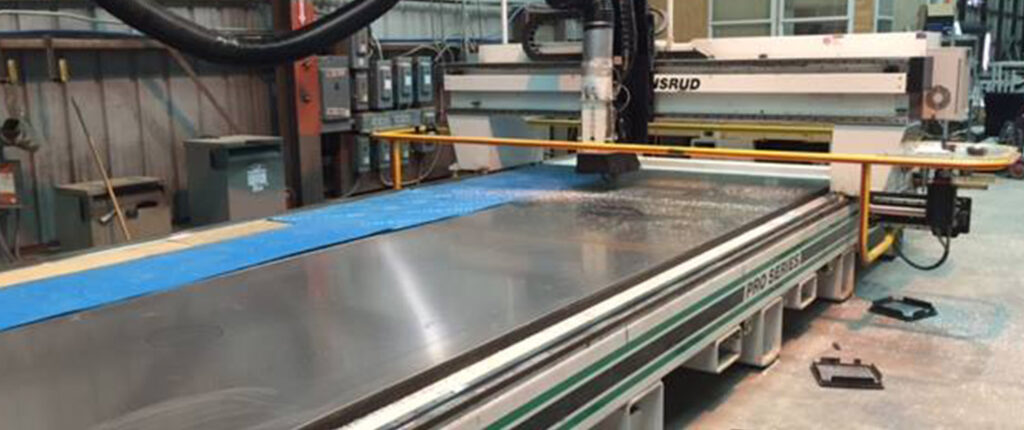

Bayou Metals offers value-added metals processing, such as precision router cutting with our (1) onsite 12’ x 68’ and (2) 8’ x 40’ CNC routers, cutting to length, plasma cutting, precision sawing, and shearing, and more, before distributing these products to manufacturers and other end-users.

In 2018, the owners formed a production company, Bayou Manufacturing Services, which extends the value-added services to include Friction Stir Welding and weld shop fabrication capabilities to our customers all on the same property.

Committed To Saving Our Customers Time & Money

CNC Routing

Bayou Metal Supply & Manufacturing Offers High-Precision CNC Milling Services Bayou Metal Supply & Manufacturing offers a wide range of metal processing services, including friction stir welding, shearing, and precision router cutting, to manufacturers and end users in Louisiana and throughout the Gulf Coast. Our extensive processing capabilities set us apart from other metal processing services. Our machine shop is equipped with three CNC routers.

Metal Bending

Friction Stir Welding

Plate Saw

9” thick x 54” wide

Shear

CNC Machining

Hassle-Free, Quality Products When They’re Needed

Helping Maintain Your Reputation & Quality

- Available Inventory, ready to ship next day on most items

- Rapid response to our customers’ needs and request

- Extensive Processing Capabilities; offering value added services