Pre-Fabrication, Kitting & Super Kitting Capabilities

Save time & Money With Ready-to-Assembly and Install Components and Parts

Bayou Metal Supply & Manufacturing is a leader in the metal supply and fabrication industry, offering top-tier pre-fabrication, kitting, and super kitting services. With ISO 9001:2015 certification and a robust infrastructure, we provide precision and efficiency in material preparation, organizing parts, and assembling components, ensuring that every project meets the highest standards of quality and reliability.

Our Pre-Fabrication, Kitting, & Super Kitting Capabilities

Ready-to-Install Components

State-of-the-Art Equipment: Our advanced facilities are equipped to handle a wide range of tasks. Key capabilities include:

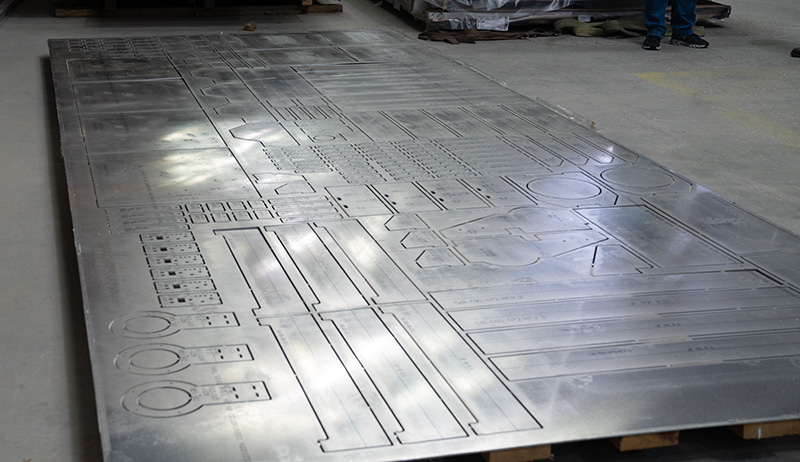

- Pre-Fabrication: Our pre-fabrication services involve any material preparation required, including single cuts, CNC machining, welding, and more. This allows us to deliver parts that are ready for immediate use, saving time and reducing labor costs on-site.

- Kitting: We meticulously separate, sort, and package parts into kits ready for immediate assembly. Our kitting services ensure that all necessary components are grouped together, reducing assembly time and improving workflow efficiency. Customers receive kits of parts needed to build each assembly per the drawings and delivery blocks, which are determined by each customer’s schedule and build strategy.

- Super Kitting: Our super kitting services take it a step further by providing partial or full assembly of components. We fabricate, assemble, and weld parts at various levels from sub-assemblies to main assemblies. This process ensures that parts are ready for immediate integration into the final product, streamlining production and reducing on-site assembly time.

- Parts Conditioning: Bayou offers comprehensive part conditioning services, ensuring all edges are deburred, cleaned, and polished, making parts ready for welding. Using our Apex edge conditioning machine and, when necessary, a hand router, we round-over and deburr each edge for a smooth finish with no sharp edges, delivering parts that are safe, clean, and prepared for immediate use.

Materials

We work with a variety of materials, including:

- Aluminum

- Stainless Steel

- Specialty Alloys

This versatility allows us to serve a diverse array of industries, providing customized solutions that meet specific material requirements.

Complex Operations

Our capabilities extend to complex operations, ensuring that we can handle both simple and intricate projects with precision and efficiency. From small-scale assemblies to large, complex builds, our team is equipped to deliver high-quality results.

Advantages of Our Services

Precision and Accuracy

Our state-of-the-art equipment and skilled technicians ensure that every pre-fabricated part, kit, and assembly is completed with the highest level of precision. This results in components that meet stringent tolerances and deliver consistent performance.

Efficiency

We utilize efficient processes that minimize waste and reduce production costs. Our fast turnaround times help meet tight deadlines without compromising on quality, providing excellent value to our clients.

Customization

We offer extensive customization options to meet the unique requirements of each project. Whether it’s a small batch or a large production run, our team works closely with clients to deliver tailored solutions that fit their specific needs.

Parts Delivered When You Need Them

Our services ensure that parts and assemblies are delivered exactly when you need them, according to your schedule. This just-in-time delivery approach helps maintain production timelines and reduces downtime, ensuring a smooth and efficient workflow.

Cost Savings with Less Build Time On-Site

By providing pre-assembled kits, components, and pre-fabricated parts, we significantly reduce the build time required on-site. This not only accelerates the production process but also lowers labor costs and minimizes potential delays, resulting in substantial cost savings for our clients.

Quality Assurance

Rigorous Quality Control: Quality is integral to our services. We implement strict quality control measures at every stage of production, including:

- Detailed inspections to ensure dimensional accuracy and functionality.

- Adherence to industry standards and specifications.

Certifications: Our commitment to quality is reflected in our certifications:

- ISO 9001:2015: This certification underscores our adherence to international standards for quality management.

- AWS and CWI Membership: We are members of the American Welding Society (AWS), and our Certified Welding Inspectors (CWI) oversee related welding operations, ensuring top-notch quality and safety.

Industries Served

Diverse Applications: Our CNC machining services are essential across various industries, including:

- Marine Industry: Durable and precise machined parts for shipbuilding and other marine applications.

- Construction and Heavy Machinery: Robust machining solutions for building infrastructure and heavy equipment.

- Automotive: High-quality parts for automotive production, meeting stringent industry standards.

- Aerospace: High-precision components for aerospace applications, ensuring reliability and performance.

We have a proven track record of delivering high-quality machined components that meet the rigorous demands of these industries.

Why Choose Bayou Metal Supply & Manufacturing?

Comprehensive Capabilities

Bayou Metal Supply & Manufacturing stands out for its advanced pre-fabrication, kitting, and super kitting capabilities, skilled workforce, and commitment to quality. Our state-of-the-art equipment and experienced technicians enable us to deliver superior results, consistently meeting the exacting standards of our clients.

Value-Added Services

Our comprehensive range of value-added services, including project management and inventory management, ensures that your production processes are streamlined and efficient. We aim to provide end-to-end solutions that enhance your operational efficiency and reduce costs.

Customer-Centric Approach

Our customer-centric approach ensures that you receive personalized support and expert advice throughout your project. From initial consultation to final inspection, our team is dedicated to providing exceptional service and ensuring your complete satisfaction.