CNC ROUTING

Large Scale, Precision CNC Routing Services

Bayou Metal Supply & Manufacturing is an ISO 9001:2015 certified manufacturer. Metal Center Service News recognizes us as a Master Distributor. Over the past few years, we have significantly expanded our capacity. In 2015, we set up a 185k sq.ft. warehouse. We established Bayou Manufacturing – a subsidiary of Bayou Metal Supply & Manufacturing in 2018. In 2022, we set up a new 40,000 sq.ft. facility.

Bayou Metal Supply & Manufacturing’s CNC Routing Capabilities

Bayou Metal Supply & Manufacturing offers top-notch CNC Router machining services. Our unparalleled ability to understand and meet client requirements sets us apart.

Our state-of-the-art CNC routers-

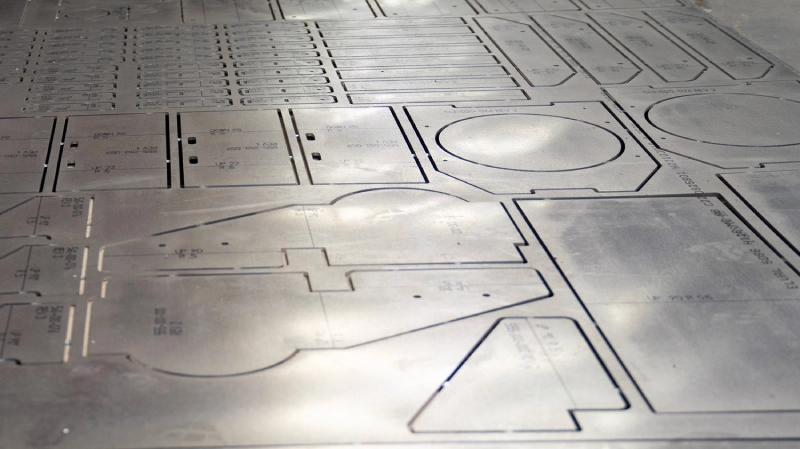

- ➢ Are designed to cut materials into complex, custom shapes and sizes

- ➢ Three routers on property with the largest table 12’ x 68’ and two (2) tables 8’ x 40’.

- ➢ Capabilities include full cut parts or parts tabbed in place. The CNC routes can etch the material or ink mark the parts with various pieces of information. This includes part numbers, bend lines/instruction and weld layouts and fit-ups.

- ➢ Boast high-precision motion components designed to maximize accuracy

Our expertise allows us to cut parts cleanly. On request, our team can etch or mark all lines in every cut/nest file. We can also apply thermal labels and carry out CNC marker plotting. Our operators are trained to use CNC routers effectively to create tapered or conical shapes, lay out cutting patterns (nesting), and identify stickers for cut parts.

On request, we can assemble cut parts, extrusions, and machined parts. Our ABS-certified welders are equipped to perform welding at any level. We can also assemble fabricated parts at any level. We have FSW qualification procedures for our operators.

Why Choose Us Over Our Competitors?

CNC routers are used in various industries, including aerospace, electronics, healthcare, and automotive, to manufacture parts with tight tolerances. They are known for their precision, accuracy, and ability to repeatedly produce parts that are exactly the same.

Our state-of-the-art CNC routers feature cutting-edge technology. Their parts are made of quality materials that stand the test of time. They can operate for hours at a stretch and cut and shape materials much faster than human operators.

Our team comprises seasoned machinists with an in-depth understanding of different CNC machining operations. They have undergone specialized training and are equipped to adapt their techniques to cut materials into custom shapes. Their know-how and experience enable them to steer clear of machining mistakes and create high-quality machined components.

Bayou Metal Supply & Manufacturing has a track record of completing complicated machining projects on time, without cutting corners or exceeding budget. Whether you want to have materials cut into custom or irregular shapes or need other metal fabrication services, our team has got you covered. We cater to different industries including construction, shipbuilding, and oil & gas. Our quality control process is designed to identify the smallest deviations and workmanship defects and reject defective products.

We assess our production process at regular intervals to identify process improvement opportunities. An effective process assessment reveals process gaps and helps us gain valuable insights into our process. Based on our findings, our team streamlines workflows and removes unnecessary steps that are wasting time.

Metal processing is a dynamic and ever-evolving industry. Metal processing methods and tools that are popular today may fail to find takers tomorrow. We stay on top of technology trends and closely follow industry news and developments. Our professionals consciously try to upgrade their skills and improve their knowledge base. They leverage their extensive knowledge of the latest technologies to create value for our customers.

Our Value Added Services

Inventory management is fraught with challenges. Often, inventory managers spend hours trying to keep track of inventory and are unable to make time for other important tasks. We offer top-notch inventory management services.

We track project progress (from quote to delivery), and share project status reports with our customers every week. Our advanced inventory management system helps production schedulers make informed decisions by allowing them to review build sequence/design whenever they want. The system enables our team to track inventory, materials, parts, assemblies and deliveries.

We operate a production friction stir welding line and can create custom panels tailored to builds. To speed up the fabrication process and reduce fabrication cost, we can router cut large panels. On request, our team can create friction stir welding extrusions in custom shapes.

Using our Apex edge conditioning machine and hand router, we debur each part ensuring they do not have any sharp edges.

Our fully automated machine shop enables us to meet diverse machining needs. We have a CNC lathe, Bridgeport Mills, CNC saws, and CNC mills with up to 24”X56” worktables.

After a kit is put together, our team carefully stacks each pallet of fabricated material on a truck for delivery. We plan deliveries down to the last detail, and ensure that no trucks are overloaded.

To talk to one of our metal specialists, call our office.

Overview of Bayou Metal Supply & Manufacturing:

Overview of Bayou Metal Supply & Manufacturing: Bayou Metal Supply & Manufacturing is an ISO 9001:2015 certified manufacturer and a Master Distributor recognized by Metal Center Service News. Over the past few years, we have significantly expanded our capacity with facilities that ensure we meet and exceed client expectations.

Our CNC Routing Capabilities

State-of-the-Art Equipment

Bayou Metal Supply & Manufacturing offers unparalleled CNC routing services with advanced equipment designed to cut materials into complex, custom shapes and sizes. Key features include:

- Heavy-Duty Steel Frame: Ensures machine stability and precise, accurate cuts.

- Low Maintenance: Our CNC routers are designed for durability and minimal upkeep.

- High-Precision Motion Components: Maximize accuracy for intricate designs.

Materials

We specialize in routing a variety of materials, including:

- Aluminum

Complex Operations

Our expertise allows us to perform operations such as:

- Etching and Marking: For all lines in every cut/nest file including part information, bending instructions and weld layouts and fit-ups.

- Thermal Labels and CNC Marker Plotting: For easy identification of cut parts.

- Tapered and Conical Shapes: Created with precision for various applications.

Advantages of Our CNC Routing Services

Precision and

Quality

Our state-of-the-art CNC routers ensure precision and quality in every cut. We provide consistent, repeatable results with tight tolerances, making our services ideal for high-volume production.

Efficiency and Cost-Effectiveness

With advanced technology and streamlined processes, we achieve fast turnaround times without compromising on quality. Our efficient services help reduce production costs and enhance overall project value.

Custom

Solutions

We offer extensive customization options to meet unique project requirements. Whether it’s a small batch or a large production run, our team works closely with clients to deliver tailored solutions.

Delivery and Timeliness

We strive to process orders within 24 hours of receipt. Our ability to fabricate and deliver ready-to-assemble parts and modular kits ensures timely deliveries and meets tight deadlines, saving clients the hassle of on-site processing.

Quality Assurance

Rigorous Quality Control: Quality is paramount at Bayou Metal Supply & Manufacturing. We implement strict quality control measures throughout the CNC routing process, including:

- Detailed inspections and tests to ensure dimensional accuracy and surface finish.

- Adherence to industry standards and specifications.

Certifications: Our commitment to excellence is reflected in our certifications:

- ISO 9001:2015: Ensures adherence to international standards for quality management.

- AWS Certification: Our Certified Welding Inspectors oversee related welding operations, guaranteeing top-notch quality and safety.

Industries Served

Diverse Applications: Our CNC routing services cater to a wide range of industries, including:

- Aerospace: High-precision components for aerospace applications.

- Construction and Shipbuilding: Robust solutions for building infrastructure and marine applications.

- Oil & Gas: Durable components meeting the rigorous demands of the industry.

Why Choose Bayou Metal Supply & Manufacturing?

Industry Leadership

Bayou Metal Supply & Manufacturing stands out for its advanced CNC routing capabilities, skilled workforce, and commitment to quality. Our state-of-the-art equipment and experienced technicians enable us to deliver superior results, consistently meeting the exacting standards of our clients.

Comprehensive Support

Our customer-centric approach ensures that you receive personalized support and expert advice throughout your project. From initial consultation to final inspection, our team is dedicated to providing exceptional service and ensuring your complete satisfaction.