Bending & Forming

Complex, Precision Forming Services, including Complete Hulls

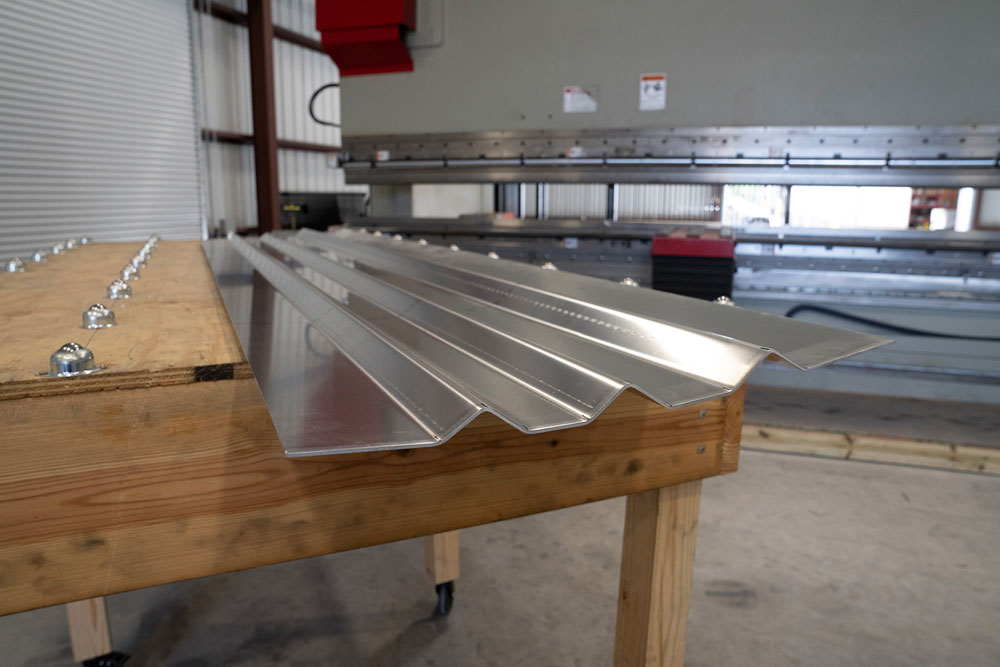

Our Forming Capabilities

Ready-to-Install Components

Our forming services include Beveling, Bending, and Sniping, all performed to exact standards based on the provided drawings and profile plots. With our CNC-controlled equipment, we ensure each part is formed with high precision, meeting the unique requirements of your project.

- Bending Precision: Bending is carried out using our CNC Press Brakes and CNC Euromac Digibend, providing exceptional control over material shaping. Our facilities support bending of up to 34 feet in length and can handle up to 1000 tons of material force, utilizing our Semi-Automatic Boat Bending Press for large-scale projects. This allows us to handle anything from small, intricate parts to large, heavy-duty components with ease.

- Beveling: For precise edge conditioning, we offer beveling services performed by our CNC Machine Shop. Each part is carefully beveled according to your exact specifications, ensuring clean, accurate edges that meet or exceed industry standards.

- Sniping: Our sniping services are available in each of our production and fabrication shops, providing an efficient way to create precise cuts on the material edges. This ensures a clean finish that requires minimal secondary processing, allowing us to deliver parts that are ready for the next stage of production.

- Specialty Bending: In addition to our plate bending capabilities, we have specialty benders that allow us to form pipe and create complex CNC shapes. This advanced capability gives us the flexibility to meet a wide variety of bending and forming needs across industries.

Materials

We have the capability to work with a wide range of metals, including:

- Aluminum

- Stainless Steel

- Specialty Metals

This versatility allows us to serve a diverse array of industries and applications, providing customized solutions that meet the specific material requirements of each project.

Complex Operations

Our expertise extends to performing complex operations with precision and efficiency. From intricate bending to precise sawing and shearing, our advanced equipment and skilled technicians ensure that every project is completed to the highest standards. We are equipped to handle both small-scale and large-scale production runs, offering flexibility and scalability to meet the varying needs of our clients.

Advantages of Our Services

Precision and Accuracy

One of the hallmarks of Bayou is our commitment to precision and accuracy. Our advanced machinery and skilled workforce ensure that each operation, whether it involves bending, sawing, or shearing, is performed with meticulous attention to detail. This results in parts that meet the strictest tolerances and specifications, ensuring high-quality outcomes for our clients.

Efficiency

Efficiency is at the core of our operations. Our state-of-the-art equipment and optimized processes enable us to deliver fast turnaround times without compromising on quality. By minimizing waste and maximizing productivity, we are able to offer cost-effective solutions that add value to our clients' projects.

Customization

We understand that each project is unique, and we pride ourselves on our ability to provide customized solutions tailored to the specific requirements of our clients. Whether it’s creating unique shapes, executing complex bends, or achieving precise cuts, our team works closely with clients to ensure that their exact needs are met. Our ability to handle both small and large production runs further enhances our flexibility and responsiveness.

Quality Assurance

Quality Control Processes: At Bayou Metal Supply & Manufacturing & Manufacturing, quality assurance is integral to our operations. We implement rigorous quality control processes at every stage of production to ensure that all parts meet the highest standards of quality and precision. Our inspections and tests are designed to detect any deviations or defects, ensuring that only the best products are delivered to our clients.

Certifications: Our commitment to quality is underscored by our ISO 9001:2015 certification, which reflects our adherence to international standards for quality management. Additionally, We are members of the American Welding Society (AWS), and our Certified Welding Inspectors (CWI) oversee related welding operations, ensuring top-notch quality and safety.

Industries Served

Diverse Applications: Bayou Metal Supply & Manufacturing & Manufacturing serves a wide range of industries, leveraging our extensive capabilities to meet the diverse needs of our clients. Our services are particularly valued in the marine industry, where precision and reliability are paramount. We have a proven track record of delivering high-quality bent, sawed, and sheared parts for shipbuilding and other marine applications, ensuring durability and performance in challenging environments.

In addition to the marine sector, we also cater to industries such as construction, automotive, aerospace, and oil & gas. Our ability to handle complex projects and deliver precise, high-quality results has made us a trusted partner for clients across these sectors. Whether it’s constructing critical components for aerospace applications or fabricating parts for automotive production, our expertise and advanced capabilities ensure that we meet the specific demands of each industry.

Why Choose Bayou Metal Supply & Manufacturing?

Competitive Edge

Bayou Metal Supply & Manufacturing & Manufacturing stands out in the industry due to our combination of state-of-the-art equipment, skilled workforce, and unwavering commitment to quality. Our advanced machinery and experienced technicians enable us to deliver superior results, consistently meeting the exacting standards of our clients. Our competitive edge lies in our ability to provide precise, efficient, and customized solutions that address the unique challenges of each project.

Customer Service

Our dedication to customer service is another key differentiator. We believe in building long-term relationships with our clients by providing exceptional service and support throughout the project lifecycle. Our team is always ready to assist with project requirements and inquiries, ensuring a seamless and hassle-free experience from start to finish. By prioritizing customer satisfaction, we have earned a reputation for reliability and excellence in the metal supply and fabrication industry.