Dissimilar Thickness Butt Welds with FSW

Dissimilar Thickness Butt Welds and Tailor Welded Blanks using Friction Stir Welding

Saving Cost and Eliminating Waste

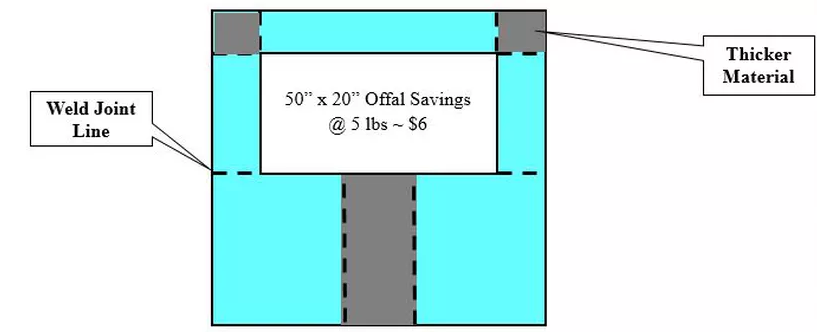

When you consider the possible material and labor cost savings from FSW of dissimilar thickness butt welds, the opportunities are enormous. Using dissimilar thickness metals can empower ship designers to put the exact thickness a plate or structure needs, with nothing wasted.

This technique is well established in automotive parts where doors and panels are often made from several different material thicknesses. Tailor welded blanks have become mainstream in many metal manufacturing industries. Bayou Manufacturing serves the aluminum shipbuilding industry using FSW to make tailor welded blanks and large panels of multiple thicknesses for modular construction in the shipyard. This provides major cost savings in raw materials, reduces displacement, and lowers overall ship hull construction costs.

Advantages of Tailor Welded Blanks

- Reduces offal and eliminates reinforcements and brackets

- Saves weight

- Reduces cost by putting the material where it is needed

- Eliminates offal/scrap

- Places thicker material in high stress areas and eliminates reinforcements and brackets

- Allows thinner material in low stress areas