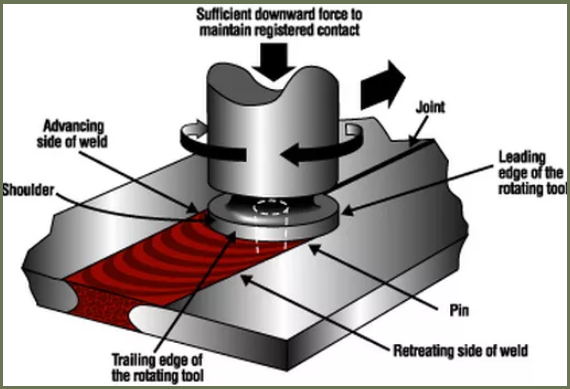

Description of Friction Stir Welds

Discover how our Friction Stir Welds can help your business

FSW Provides Cleaner and Stonger Welds

The FSW delivers numerous advantages over other welding technologies. It is used to weld a wide range of materials including aluminum, steel, plastic, titanium, copper, and magnesium. Butt and lap joints are the most common types of welds for FSW and also the simplest. Bayou also does FSW Spot Welding in some applications. A key advantage is that less surface preparation is needed but it’s vitally important to hold the plates tightly in place. The machinery for that is a critical part of the process. Fillet welds can also be done with FSW and it’s excellent at joining dissimilar metals, with proper engineering weld design to get the right setup.

FSW advantages over traditional welding processes include:

- Improved ductility, fatigue and fracture toughness

- High yield strength (up to 80% of base metal) in large aluminum panels. In testing, failures are often in the base material first.

- Fatigue life of friction is greatly improved over laser and MIG welding.

- Fracture toughness is also higher.

- Corrosion resistance is also very good.

- The application to LARGE aluminum panels offers tremendous cost advantages in the manufacturing, particularly for very long panels. (Our Bayou FSW line is almost 200 ft long.)

- Lower temperatures of FSW are an advantage for welding thick aluminum skins of honeycomb panels.

- Dissimilar material welds can be made successfully, with solid engineering design before welding.

- No consumables, the tool is non-consumable. This is significantly more environmentally friendly.

- Extremely high quality, low defect bonds

- Minimum distortion of the joined parts

Friction Stir Welding is Preferred in a Wide Variety of Market Sectors

The friction stir welding process is being used within the aerospace, military vehicle, aircraft, automotive, shipbuilding, railway rolling stock industries, and a growing list of other applications.

The other two basic configurations for friction welding are:

Rotary Friction Welding

This is a very popular type of friction welding. At least one of the parts is rotationally symmetrical, usually a tube or bar.Linear Friction Welding

A more advanced technique for engine components, near-net manufacturing- Affords new joining applications for difficult manufacturing challenges- from extrusions to sheets and more

- Virtually defect-free bonding

- Accommodates parts up to 55 feet long

- Ability to join dissimilar alloys

- Ability to use dual head feature for fast panel welding

- Minimal distortion of joined parts, for extremely high-weld strength

- Eco-friendly since no consumables are used

- For aluminum particularly, lower distortion is created with the lower heat, and porosity problems associated with aluminum arc welding are eliminated.