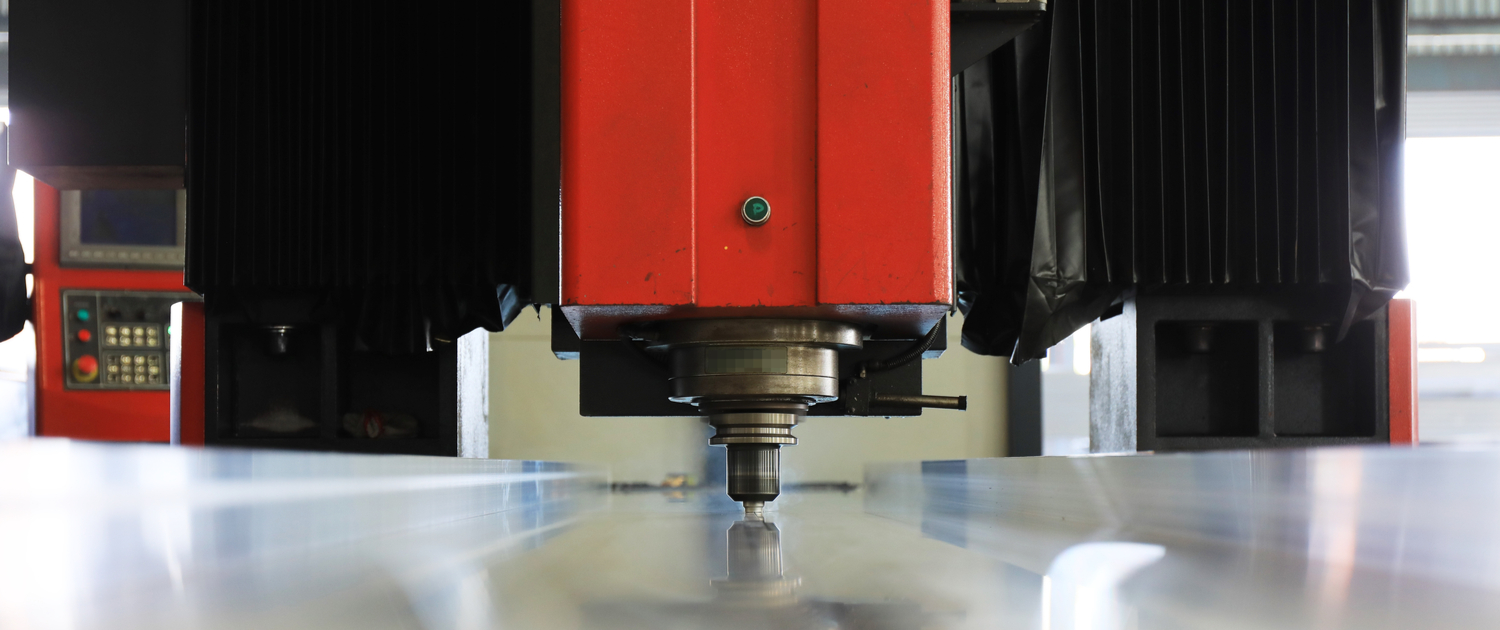

How it works

Friction welding has generally been applied to two-dimensional butt welds, i.e. straight line welds created by a rotating tool creating friction and plasticizing the weld area. Bayou specializes in these basic welds in long lengths and large numbers of welded panels to provide aluminum shipbuilding modules. However,

friction welding is well adapted to a wide range of other kinds of welds and different materials.

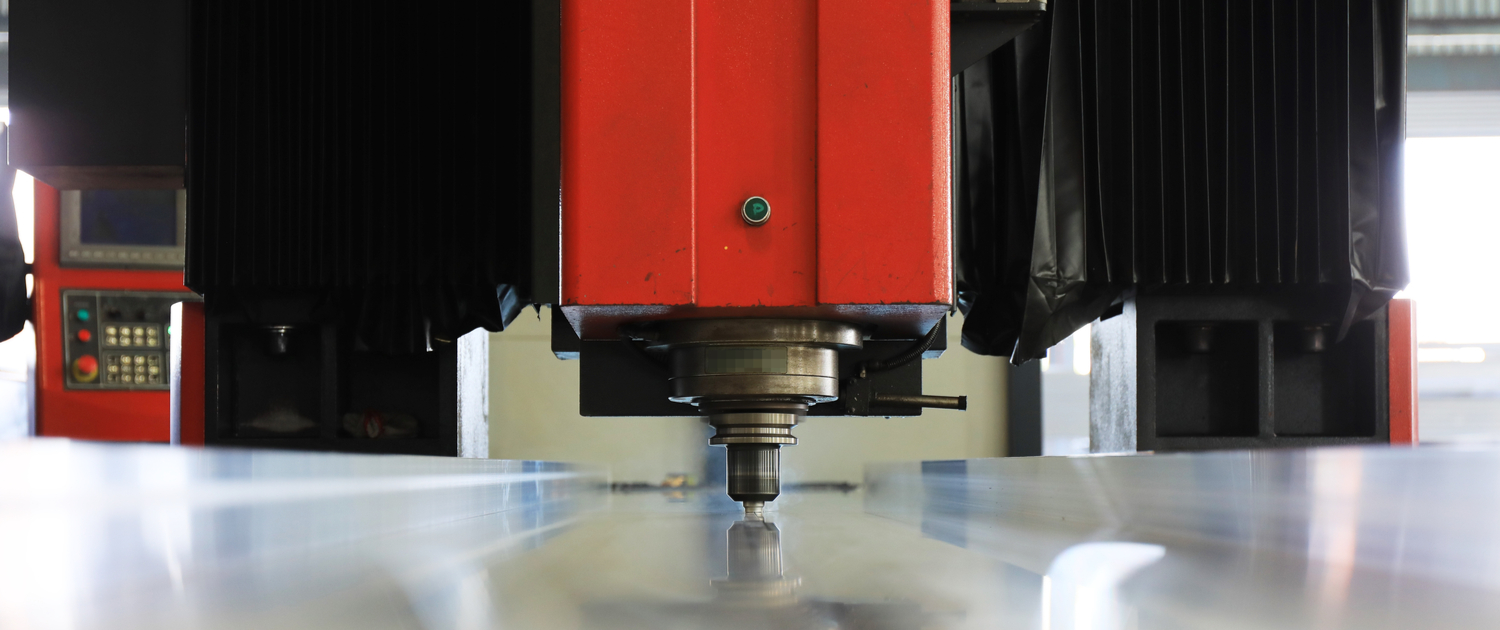

Curvilinear welds are a perfect example of an unusual capability for friction stir welding. Curvilinear welds are popular for complex shapes used in the aerospace and automotive industries. Where complex shapes are mandatory for the part design and yet different types or thicknesses of material are also essential, a curvilinear weld becomes necessary. These welds become more in demand as applications become more complex and weight reduction more important. Bayou has experience with curvilinear friction stir welding in shipbuilding and railcar applications.

The Best Choice For Challenging Welds

Friction stir welding is also very well suited for welds whose orientation would be considered difficult in Gas Metal Arc Welding (GMAW) such as vertical welds or “out-of-position” welds. This advantage exists because GMAW melts metal which wants then to run out of the weld zone due to the effects of gravity.

Friction stir welding only plasticizes the material being welded.

As with curvilinear welds, out of position and other difficult orientations require advanced welding process design engineering for success. An experienced company like Bayou that focuses on FSW welding can make those calculations, run validation tests, and create a unique welding process for your application.

Friction stir welding applies well to castings, forgings, extrusions, and wrought material such as sheet and plate. It can also be successfully used to join castings to wrought material, extrusions, and forgings. Light alloy casting welding by FSW has proven to be an excellent technique with superior mechanical properties. Even high-pressure die-cast magnesium plates have been friction stir welded with success. A unique application of FSW was the welding of Wrought Homogenous Armor to aluminum panels to create lighter overall weight and high armor protection where it was needed.

These are just a summary of how Friction Welding can be applied to many unique materials, mechanical configurations, and applications.

Call Bayou Manufacturing to discuss your next project with our engineers and production process experts!